PVC

PVC products

The exceptional properties of PVC together with its good quality / care ratio and its great versatility make it the most widely consumed plastic in the world. Besides its versatility, PVC is a light, resistant, inert and completely innocuous material, with good behavior to fire (it does not spread the flame, it is self-extinguishing). Impeccable insulator (thermal, electrical and acoustic), weather resistant and fully recyclable. The diversity of possible formulations makes PVC the most versatile of plastics, allowing it to adapt to very diverse applications and requirements. No other type of material has been developed as powerfully in such a short time as plastic windows.

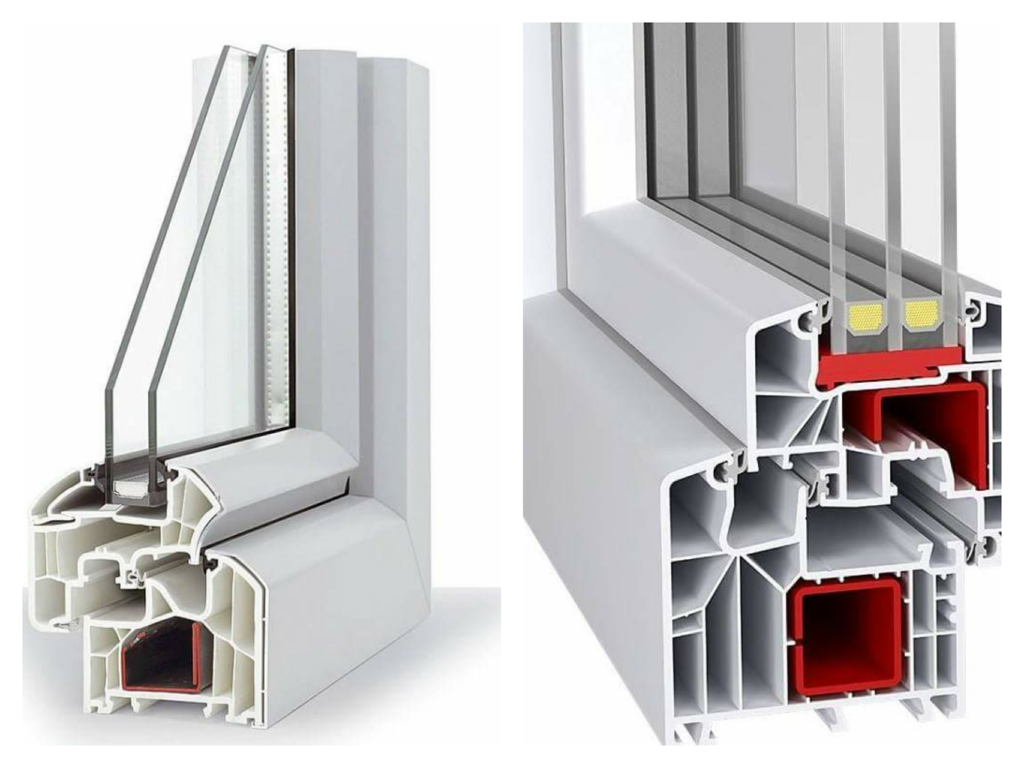

The building materials industry can no longer do without them. Advantage is taken of its insulating properties, its resistance to corrosion, its low weight, its insensitivity to humidity and its rottenibility. Plastics have set new standards in window technology. Continuous improvements and efficient quality control have made PVC windows highly developed building elements.

ACOUSTIC ISOLATION

Sound is a disturbance or excitement that is prolonged through an elastic medium such as air. When this sound is an unwanted sound it becomes noise. PVC as a thermoplastic material is one of the most insulating materials because it absorbs the vibration waves emitted by noise. Its design, its permeability to air and its lightness are fundamental factors to achieve this quality. Other factors that also influence are the type of glazing and the inclusion of elements such as air chambers, the number of closing points that will be present and the pressure that these points will exert.

DO NOT SPREAD THE FIRE

PVC, due to its composition, is a self-extinguishing and hardly flammable material, it is consumed slowly and with difficulty, which makes it a material that does not contribute to a fire or its development.

RESISTANCE TO WEATHER AND AGING

All materials exposed to the elements suffer gradual degradation caused by atmospheric agents in which physical, chemical, biological and mechanical agents intervene over time. These agents produce alterations in the materials, affecting their characteristics such as discoloration, structural changes, etc. In the case of PVC profiles for windows, tests have been carried out for their verification and guarantee mainly. Outdoor exposure tests in hot-humid and hot-dry climates have proven for many years that increasing the amount of light stabilizing pigments provides efficient protection against radiation.

RESISTANCE TO TEMPERATURE VARIATIONS

The coefficient of expansion in the profiles manufactured for windows is minimal, due to: * Low coefficient of thermal conductivity. * The geometry of the profile makes it absorb a large part of these expansions. The design of the PVC profiles are hollow with partitions which notably increases their insulation.

RESISTANCE TO MOISTURE, BIOLOGICAL AND CHEMICAL AGENTS

PVC is a material that practically remains unchanged against the action of aggressive environments present in urban, industrial or saline areas. They have a very good outdoor behavior, as well as the action of chemicals, it does not need